Life Cycle Assessment: Evaluating Environmental Impacts of Products and Processes

In an era of increasing environmental concerns, assessing the ecological impacts of products and processes has become crucial for sustainable decision-making. Life Cycle Assessment (LCA) offers a comprehensive methodology to evaluate these impacts throughout the entire life cycle of a product or process. Learn about LCA's methodology, steps, product cycles, and its benefits for sustainable decision-making and discover how LCA can optimize resource utilization, engage stakeholders, and drive positive change.

What is LCA?

LCA is a systematic approach that analyzes a product's or process's environmental impact from the cradle to the grave. It encompasses all stages, from the extraction of raw materials, through manufacturing, distribution, use, and end-of-life management. By considering the full life cycle, LCA provides a holistic perspective on environmental sustainability, enabling informed decision-making and the identification of areas for improvement.

How is LCA done?

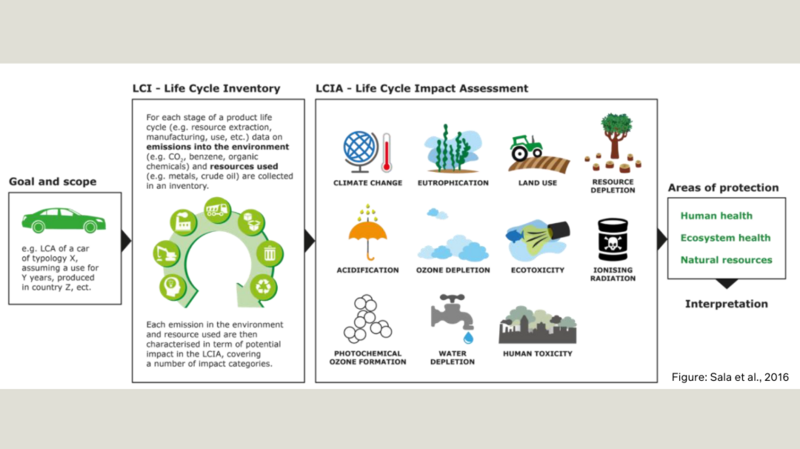

Life Cycle Assessment follows a systematic and structured approach to assess the environmental impacts of products and processes. By considering the entire life cycle, LCA provides a holistic understanding of environmental burdens and benefits associated with each stage. It consists of several steps, each playing a crucial role in the assessment process:

- Goal and Scope Definition: This initial step clearly defines the study's objectives, boundaries, and functional unit. It determines the system under analysis, the environmental categories to be considered, and the intended use of the results.

- Life Cycle Inventory (LCI): LCI involves collecting data on all inputs (e.g., raw materials, energy) and outputs (e.g., emissions, waste) associated with each life cycle stage. Various data sources, including databases, literature, and industry statistics, are utilized to develop a comprehensive inventory.

- Life Cycle Impact Assessment (LCIA): LCIA evaluates the potential environmental impacts of the identified inputs and outputs. Using impact assessment methods and models, it quantifies and assesses impacts in categories such as climate change, resource depletion, acidification, and eutrophication.

- Interpretation: The interpretation step involves analyzing and summarizing the results of the LCA study. It includes identifying significant environmental issues, evaluating uncertainties, and communicating the findings effectively to stakeholders.

Product Life Cycles in LCA:

The life cycle of a product encompasses a series of interconnected stages that span from its inception to its ultimate disposal. Starting from Raw Material Acquisition, LCA examines the manufacturing and production processes, the distribution and transportation of the product, the phase of use and operation, and finally, the end-of-life management. By comprehensively understanding each phase, LCA allows for a thorough assessment of environmental impacts and identifies opportunities for improvement.

Raw Material Acquisition:

This phase involves extracting or harvesting raw materials required for the product. It considers the environmental impacts of resource extraction, such as land degradation, water consumption, and biodiversity loss.

Manufacturing and Production:

Raw materials are transformed into the final product during this stage. Energy consumption, emissions, and waste generation associated with manufacturing processes are assessed, highlighting potential areas for energy efficiency and waste reduction.

Distribution and Transportation:

This phase involves transporting products from manufacturing facilities to consumers. It considers the energy consumption, emissions, and packaging materials associated with transportation, aiming to optimize logistics and reduce carbon footprints.

Use and Operation:

This stage involves the product's utilization by consumers. Energy consumption during product use, maintenance, and potential emissions or waste generation are evaluated. The use phase often presents significant opportunities for environmental improvements, such as energy-efficient design and behavior changes.

End-of-Life Management:

This final phase addresses the product's fate at the end of its useful life. It considers various scenarios, including recycling, disposal, or energy recovery. Proper waste management practices and material recycling are vital in minimizing environmental impacts.

What is the Difference Between Life Cycle Models?

Life Cycle Assessment offers various models that frame the analysis based on specific objectives and system boundaries. Key differences exist between life cycle models commonly used in LCA studies, such as Cradle-to-Grave, Cradle-to-Gate, Cradle-to-Cradle, Cradle-to-Cradle Certified™, and Gate-to-Gate. Stakeholders can select the most appropriate LCA framework by understanding each model's unique focus and scope.

Cradle-to-Grave: This model evaluates the entire life cycle of a product, from raw material extraction to final disposal. It provides a comprehensive assessment of environmental impacts throughout all stages.

Cradle-to-Gate: This model focuses on the life cycle stages from raw material acquisition to the factory gate or the point of product leaving the manufacturing facility. It excludes distribution, use, and end-of-life stages, making it useful for assessing manufacturing processes or comparing production sites.

Cradle-to-Cradle: The cradle-to-cradle model emphasizes the concept of a circular economy, aiming to design products and processes that generate no waste. It focuses on creating closed-loop systems where materials are recycled or reused, ensuring continuous resource utilization and minimizing environmental impact.

Cradle-to-Cradle Certified™: This specific certification program evaluates products based on criteria related to material health, material reutilization, renewable energy use, water stewardship, and social fairness. It encourages the development of safe, circular, and environmentally beneficial products.

Gate-to-Gate: The gate-to-gate model assesses the environmental impacts of a specific stage or process within a product's life cycle, such as a particular manufacturing process. It provides a narrower focus, enabling in-depth analysis of individual steps or processes.

Nevertheless, the Life Cycle Assessment is not immune to criticism. Several areas of concern have been raised regarding LCA, including data availability and quality, system boundary definition, methodological choices, interpretation of results, and broader limitations.

One significant criticism revolves around data availability and quality. Conducting a comprehensive LCA requires gathering accurate and reliable data on inputs, outputs, and environmental impacts throughout the entire life cycle of a product or process. However, obtaining such data can be challenging, especially for complex supply chains and emerging technologies. Insufficient or outdated data can introduce uncertainties and undermine the accuracy and reliability of LCA results.

Another point of contention is the definition of system boundaries. Establishing the scope of an LCA study involves subjectivity and judgment, as decisions must be made regarding which stages and impacts to include or exclude. Different system boundaries can yield divergent assessments of environmental impacts, making it difficult to compare studies and reach a consensus on the extent of the assessment.

Methodological choices employed in LCA have also been criticized. These choices include selecting impact assessment methods, assigning weights to impact categories, and handling uncertainties. Critics argue that the subjectivity in making these choices can introduce biases and limit the objectivity of LCA findings, potentially affecting the credibility and reliability of the results.

Interpreting LCA results poses another challenge. The complexity of environmental impacts and the trade-offs between different impact categories can make interpretation subjective. Stakeholders may have varying interpretations or weighting preferences for different impacts, which can lead to differing conclusions drawn from the same LCA study. Furthermore, the presentation and communication of LCA findings can sometimes be oversimplified or misleading, potentially resulting in misinterpretation or misrepresentation of the results.

In addition to these specific criticisms, broader limitations of LCA have also been acknowledged. LCA primarily focuses on environmental impacts and may not fully capture other dimensions of sustainability, such as social or economic aspects. Consequently, it may not address issues like social justice, ethical considerations, or cultural impacts that are also significant in sustainability assessments. Furthermore, LCA does not account for future changes in technology or market dynamics, limiting its ability to predict the long-term sustainability of products or processes.

While LCA offers valuable insights, it is crucial to recognize its limitations and potential shortcomings. Ongoing research and development in LCA methodologies, improvement in data availability and quality, transparency in decision-making processes, and broader integration of sustainability considerations can help address these criticisms and enhance the effectiveness and credibility of LCA as a decision-support tool.

Life Cycle Assessment plays a role in evaluating and improving the environmental performance of products and processes. By considering the entire life cycle, LCA provides a holistic understanding of environmental impacts, helping stakeholders make informed decisions and drive sustainable practices. While LCA has challenges, including data requirements and uncertainty, its benefits in informed decision-making, identification of hotspots, and standardization make it an indispensable tool for advancing sustainability goals. As businesses and society strive for a more sustainable future, applying and developing LCA will be crucial in guiding environmental management and driving positive change.