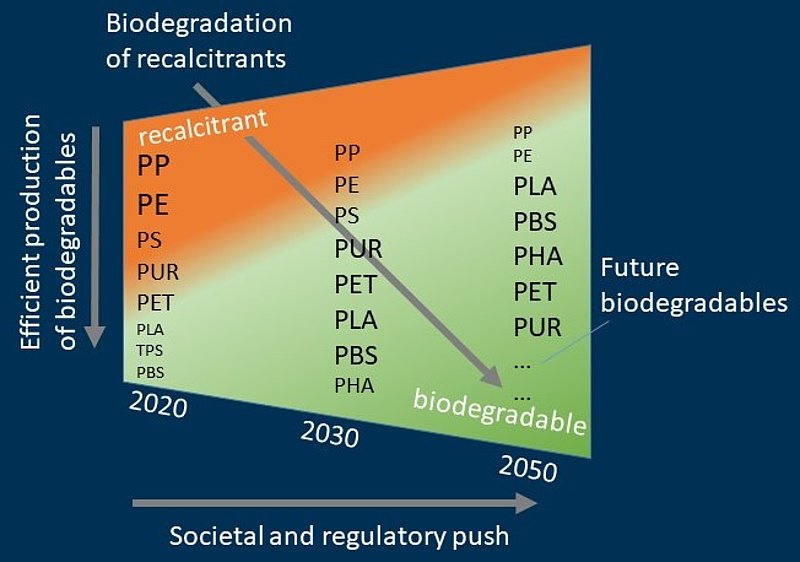

Almost 350 million tonnes of plastics are produced world-wide and a staggering 800 million tonnes are forecasted to be produced by 2050. By way of contrast, only a small fraction of that plastic is recycled. The result: valuable resources get lost, and our environment is polluted. The European Commission (EC) has set the goal of transforming the EU into a resource-efficient economy with an emphasis on plastic waste treatment. In early 2020, the National Development and Reform Commission (NDRC) and the Ministry of Ecology and Environment (MEE) of P. R. China also put forward new policies and implementation programme in further strengthening plastic pollution control. This transformation of linear value chains towards a circular bioeconomy is a far-reaching change in the plastic strategy for both Europe and China with MIX-UP born out of this vision – because plastic itself is a valuable product, we simply deal with it the wrong way. We, the participants of the MIX-UP project, make a strong commitment to helping the EC and China realise this vision by researching new ways to an efficiently use of mixed plastic waste streams.

Details about MIX-UP

Besides the need to reuse and recycle conventional plastic, new solutions to upcycle plastic mixtures into resistant and biodegradable plastics are also urgently needed. MIX-UP combines both by using these plastic mixtures as a starting material for biotechnological conversion into value-added, sustainable biomaterials.

Global problems require global solutions, international cooperation, and a holistic view of the problem. The consortium of MIX-UP includes in total 14 partners from all over the world with the effort of coordinators originating from the two leading plastic producers: the European Union and the P.R. China. MIX-UP is also addressing the industry to tackle the long-term use of mixed plastic on an industrial scale. Besides, we start a step earlier: we address the public to draw attention to the problem and provide scientific insights into our work to establish a long-term sustainable bioeconomy. Altogether, the MIX-UP consortium includes seven universities and three research centres, complemented by two partners from large industry and small/medium-sized enterprises (SMEs), respectively.

Our concept

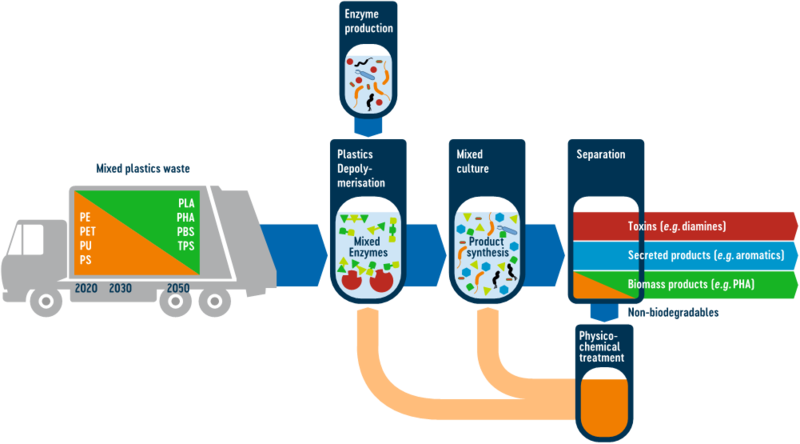

The main idea of MIX-UP is to showcase a novel approach to the circularity of the plastic life cycle. First, the unsorted plastic waste needs to be mechanically pre-treated. A further preliminary step before the actual upcycling is to produce enzymes in defined microbial mixed cultures and synthesised in an optimised production reactor (enzyme production).

Next, the shredded waste is exposed to those engineered enzyme blends to hydrolyse the polymers into their smaller components (mono- and oligomers). For this first and essential step (plastic depolymerisation), a mixture of different enzymes is required that can handle the different types of plastic present.

The released plastic mono- and oligomers from the various plastics-types are transferred to a mixed culture bioreactor. Here, these mono- and oligomers can be used as plastic derived feedstock and fed to dedicated microbial communities able to bioconvert these components into new components. Afterwards, these new components provide the building blocks for the synthesis of novel biopolymers e.g. the bioplastics like the polyhydroxyalkanoates / PHA.

Besides bioplastics, toxins and other secreted products are released during the upcycling process. Therefore, MIX-UP will tackle the issue of downstream processing and recovery of the product by, for example, conditional release of the intracellular products and separation. The plastics waste recalcitrant residues will be subjected to chemical transformations (physico-chemical treatment), thereby synthesising valuable chemicals and closing the MIX-UP cycle by re-entering into the bioprocess.

On this background, MIX-UP proposes the engineering of a new-to-nature biological route for the conversion of mixed plastics waste to added value bio-products, which will empower the recycling industry to a qualitatively new dimension. When successful, mixed plastics wastes can be established as novel second-generation carbon sources for bio-products, helping to solve the conflict of food vs fuel that is pervasive in contemporary Industrial Biotechnology. Thus, through a combination of intensive protein engineering, metabolic engineering of defined mixed cultures and bioprocess-optimisation, MIX-UP will enable new value chains across sectors like materials, chemicals, and environmental technologies within the framework of a sustainable knowledge-based bio-economy. MIX-UP will ultimately be to the benefit of the economy, environment, and society at large.